CARB 2 compliance is an important regulatory standard for manufacturers in the furniture, cabinetry, and flooring industries.

Created by the California Air Resources Board (CARB), it sets strict limits on formaldehyde and VOC emissions from composite wood products. Formaldehyde, a common indoor pollutant, is linked to respiratory issues and increased cancer risk.

For contractors, furniture brands, and cabinet makers, meeting CARB 2 compliance is essential—not just for legal reasons, but to protect consumers and align with growing health and environmental expectations.

As more states adopt California’s standards, CARB 2 compliance is becoming a national—and global—requirement, not just a regional one.

Navigating Formaldehyde Regulations for Home Materials

Deciphering the rules around formaldehyde regulation and labeling is key if you want to ensure the products you purchase are compliant for formaldehyde emissions. Whether you’re building a home, undergoing a renovation, or planning a remodel, you’ve probably come across the term “CARB P2 compliant.” This designation refers to strict standards designed to reduce the presence of harmful pollutants—especially the “new home smell” that comes from new cabinets, flooring, carpets, paint, or furniture.

That smell is caused by volatile organic compounds (VOCs), which can negatively impact indoor air quality and trigger symptoms like headaches, itchy eyes, and respiratory irritation. One of the most common VOCs is formaldehyde, which is frequently found in composite wood products.

To address these concerns, public health agencies in the U.S. and Europe have set formaldehyde emission limits. In the U.S., the Environmental Protection Agency implemented a nationwide labeling rule—effective June 1, 2018—requiring wood products to be labeled if they are compliant for formaldehyde standards. While CARB 2 compliance ensures safer indoor air quality, homeowners should also consider how other design choices, like entryways and doors, impact overall home safety and style. For practical guidance, see our Tips to Choose a Front Door to complement your low-emission, eco-conscious interior selections.

Below, we break down what CARB P2 compliant means, why it matters, and how to determine if a product you’re considering meets the latest formaldehyde regulations.

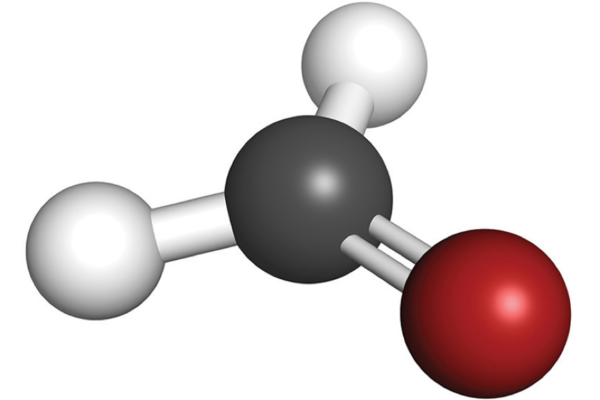

Understanding formaldehyde

Formaldehyde is a naturally occurring, colorless gas with a strong, pickle-like odor. While it exists in small amounts in nature and is even found in natural wood, it becomes hazardous at high concentrations. Classified as a volatile organic compound (VOC), formaldehyde easily vaporizes at room temperature and is commonly released into indoor air through a process known as off-gassing.

This compound is widely used in paints, adhesives, household cleaners, landscaping products, personal care items, and in the resins that bond composite wood materials—including those used in kitchen cabinets. It is also used as a disinfectant and preservative in medical and mortuary environments. However, formaldehyde is a known human carcinogen, and long-term exposure can cause serious health risks, particularly respiratory issues.

To protect consumers, regulations now require that many wood-based products be compliant for formaldehyde, especially those used indoors. Products that are phase 2 compliant for formaldehyde meet stricter emission limits established by the California Air Resources Board (CARB), helping ensure better indoor air quality and safer living environments.

What Does CARB Phase 2 Compliant (CARB2 Compliance) Mean?

What is carb phase 2 compliance? CARB Phase 2 compliant—also referred to as CARB2 compliance—is a certification standard set by the California Air Resources Board (CARB) to reduce formaldehyde emissions from composite wood products including wood flooring. This regulation is part of CARB’s Airborne Toxic Control Measure (ATCM) and plays a critical role in protecting indoor air quality and public health.

What it covers

CARB2 compliance applies to a wide range of composite wood products, including:

- Particleboard

- Medium-density fiberboard (MDF)

- Thin MDF

- Hardwood plywood

Finished goods containing these materials (such as furniture, cabinets, and flooring)

Formaldehyde emission limits

The CARB Phase 2 regulation sets strict limits on the amount of formaldehyde these materials can emit:

- Particleboard: 0.09 parts per million (ppm)

- MDF: 0.11 ppm

- Thin MDF: 0.13 ppm

- Hardwood plywood (veneer core): 0.05 ppm

|

Product Type |

Maximum Emission Limit |

|

Hardwood Plywood – Veneer Core |

0.05 ppm of formaldehyde |

|

Hardwood Plywood – Composite Core |

0.05 ppm of formaldehyde |

|

Medium-Density Fiberboard (MDF) |

0.11 ppm of formaldehyde |

|

Thin Medium-Density Fiberboard (Thin MDF) |

0.13 ppm of formaldehyde |

|

Particleboard |

0.09 ppm of formaldehyde |

Why CARB2 compliance matters

Formaldehyde is a chemical commonly found in adhesives and resins used in wood products. It is a known irritant and potential carcinogen. CARB Phase 2 compliant products are designed to reduce formaldehyde exposure, helping to create safer indoor environments and minimize long-term health risks.

How compliance is achieved

- Manufacturers must use low-emitting resins or alternative adhesives.

- Products must undergo testing by CARB-approved third-party certifiers (TPCs).

- Compliant products are labeled with statements like “CARB Phase 2 Compliant” or “TSCA Title VI Compliant” (a related federal standard).

Impact beyond california

Although CARB2 compliance originates in California, it has become a de facto national standard. Many manufacturers and retailers across the U.S. choose to meet these regulations due to California’s market influence and increasing consumer demand for low-emission, eco-friendly products.

Types of products affected

Many finished products made from composite wood materials—such as kitchen cabinets, bathroom vanities, shelving, furniture, engineered hardwood flooring, baseboards, interior doors, picture frames, and children’s toys—must meet CARB 2 compliance standards to ensure low formaldehyde emissions and safer indoor air quality.

How to know if a product is compliant

The bottom line is that all products sold in the United States must meet formaldehyde emission regulations, with CARB 2 compliance being mandatory since 2010—and most reputable manufacturers follow these standards. However, some uncertified products, especially those manufactured overseas, can still enter the market. For instance, Lumber Liquidators was previously in the news for selling Chinese-made laminate flooring that failed to meet health and safety requirements.

The European Union often enforces regulations that are as strict or even stricter than those in the U.S. At European Cabinets & Design Studios, we proudly offer CARB phase 2 compliant furniture and wood products. The majority of our inventory is 100% Made in Italy by manufacturers deeply committed to environmental responsibility and occupant health.

In short, every product we sell—whether it’s kitchen cabinets, bathroom vanities, custom closets, flooring, staircases, or doors—is CARB P2 compliant or exceeds those standards. Click to view a complete list of our trusted manufacturing partners.

Labeling: CARB 2 vs. TSCA Title VI vs. E1…

CARB Phase II has become the national standard for formaldehyde emissions in the U.S., and products must meet strict testing requirements to be considered CARB 2 compliant. To achieve this, manufacturers must pass quality control testing conducted by certified third-party agencies. Approved products are typically labeled as “California 93120 Compliant for Formaldehyde” or “California Phase 2 Compliant,” reflecting their CARB 2 compliance.

The Formaldehyde Emission Standards for Composite Wood Products Act of 2010 established a national benchmark aligned with California’s stringent rules. Since June 1, 2018, the U.S. Environmental Protection Agency (EPA) has enforced a final rule requiring all composite wood products manufactured or sold in the U.S. to carry labels indicating either CARB ATCM Phase II or TSCA Title VI compliance. As of March 2019, all products must be labeled TSCA Title VI compliant.

While imported products must follow U.S. standards, some may also carry international labels. For example, the E1 label is a European standard that allows formaldehyde emissions up to 0.10 ppm in MDF. France uses a scale from A+ to C, and Japan’s labels range from F✫✫✫ to F✫✫✫✫. Skema’s laminate flooring, for instance, holds both E1 and A+ certifications.

Achieving CARB 2 compliance is not just a labeling formality—it requires rigorous testing and ongoing verification. Only a select number of approved third-party agencies are authorized to certify that products meet these strict standards for low formaldehyde emissions.

Tips for Reducing Formaldehyde Exposure in Your Flooring

To minimize exposure to formaldehyde in your home, consider the following tips:

- Choose prefinished flooring that meets CARB 2 compliance standards to ensure low formaldehyde emissions.

- If you’re installing unfinished wood floors, opt for finishes that are not acid-cured, as these typically contain higher levels of formaldehyde.

- Limit exposure to cigarette smoke, wood smoke, and exhaust from combustion engines, all of which can release formaldehyde.

- Maintain indoor humidity below 50% and avoid high household temperatures, which can increase off-gassing.

- Improve ventilation in your home, especially when using products that contain volatile organic compounds (VOCs).

Conclusion

CARB compliance plays a vital role in ensuring that cabinets are safe for indoor use, environmentally responsible, and legally fit for sale.

For contractors, furniture brands, and manufacturers, selecting CARB 2 compliant products is a proactive step toward protecting consumer health and strengthening brand credibility.

Partnering with trusted manufacturers like Casta Cabinetry allows businesses to deliver high-quality, eco-conscious cabinets that align with the most stringent environmental regulations.

As demand for safer and more sustainable home products continues to rise, CARB 2 compliance remains a key differentiator in the competitive cabinetry market.